Quality Control

External Visual Inspection

External Visual Inspepction is a process of checking the quantity of parts, internal package, moisture indicator, desiccation and external package; And then verifying secondary coating, pin condition, sanding marks, foreign materials, manufacturer’s logo position and fonts printed including date code and country of origin. |

|

Solderability Test

The standard of solderability test is J-STD-002B, which mainly detects whether the solder capability of the pin is up to standard.

| Decapsulation Decapsulation is mainly to use the instrument to corrode the package on the surface of the chip, check whether there is a wafer inside, the size of the wafer, the manufacturer's logo, the copyright year, and the wafer code to determine the authenticity of the chip. |

Programming

We use programming equipment that supports testing 47,000 IC models produced by 208 IC manufacturers. Available include: EPROM, parallel and serial EEPROM, FPGA, configuration of serial PROM, flash memory, BPROM, NOVRAM, SPLD, CPLD, EPLD, microcontroller, MCU and standard logic device detection.

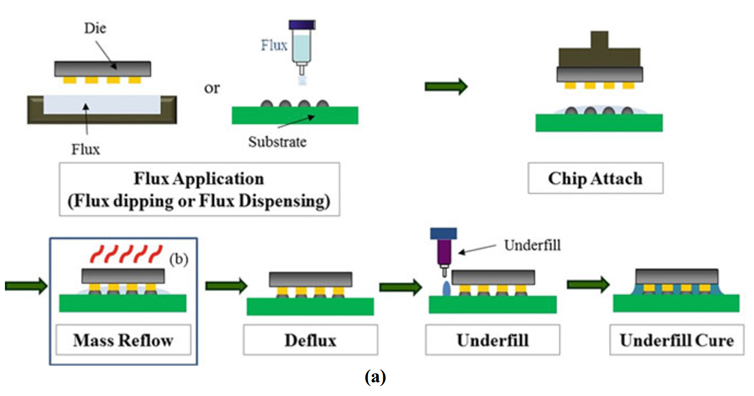

X-Ray Test X-Ray test is a real-time non-destructive analysis to check the hardware components inside the components. It mainly checks the lead frame of the chip, wafer size, gold wire binding diagram, ESD damage and holes. Customers can provide available samples or remainder of an advance purchase for comparative inspection. |

|

Electrical Characteristic Test

According to the device pins and related instructions specified by the manufacturer in datasheet, use the semiconductor tube characteristic diagram to check whether the chip is damaged by open circuit or short circuit test.

| Failure Analysis Through professional failure analysis equipment, and analysis methods to help customers analyze the cause of customer product failure and give failure analysis report and analysis conclusions. |